The innovative seed enhancer Incotec has been active in India since 1995. The big question at their market entry in India: how do we sell our solution, which is expensive by Indian standards, to the farmers there? expensive solution to the farmers there? The answer turned out to be a product specially developed for the Indian market. "It is still our top seller," says Erik-Jan Bartels, managing director of Incotec.

Managing director of Incotec Europe Erik-Jan Bartels

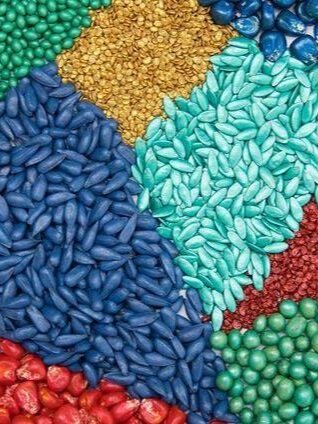

Incotec coated seeds

No genetic engineering

"When people think of seed improvement, they quickly think of genetic modification of the characteristics of the seed, or breeding, but that is not what Incotec does," explains Bartels. "With our technologies, we improve the seeds without altering the plant's DNA. For example, we put a special layer, a coating, on the seeds so that they become nicely rounded and can be sown more easily with a machine, without breaking." But Incotec's key technology goes one step further. "We can make sure that all the seeds germinate at the same time and the crop also comes up in one go. That can give a farmer a lot of extra income in a harvest, but it does come at a price."

In India, you cannot have a product that is geared towards Europe

In India, Incotec is focusing on a simpler product. "We have developed seed coatings especially for the Indian market, which not only fully meet local requirements in terms of properties and price, but can also be applied to the seed by the seed companies themselves," Bartels explains. "That is not only the first product with which we made our market entry, but it is also still one of our top sellers." Incotec arrived in India as early as 1995. The company placed an advertisement about its innovative solutions in an Indian agricultural magazine and shortly afterwards they received a fax about it. A student of Plant Breeding and Genetics at the University of Gujarat saw the potential of Incotec's products in the untapped Indian market. "This student, Manish Patel, became our first importer in India and has now been Incotec's Managing Director for 17 years. He embarked on the adventure with us from the very beginning, in the first years by trial and error," says the Dutch foreman.

While exploring the market with Patel, Incotec immediately found that even their simplest European products were still far above the budget of Indian farmers. "Producing in India was really not an option for us at that time," says Bartels. "We wanted to prevent our techniques and recipes from leaking abroad. So we first started exporting the coating developed in the Netherlands for the Indian market. That was manageable in the first few years, because our sales came on very steadily. But as soon as Incotec became better known among the large Indian seed companies, the number of orders suddenly came flooding in, and it was time to take a closer look at the way we work.

Made in India builds trust in your product

"When you're growing so fast you want to be able to respond to customer needs easily and quickly, and that's only possible if you're close to the market," says the managing director. "So we decided to set up a production facility anyway, even though we were a bit apprehensive about whether we could protect our techniques that way." Incotec therefore starts small, mixing the coating concentrate in the Netherlands and adding Indian raw materials in India and bringing the solution to the right concentration. "That felt very safe, because in India nobody knew what was in the Dutch mixture and on the basis of the raw materials there was no possibility of reverse engineering," says Bartels. "It did make a huge difference to our sales. In India, the customer likes it when you are Made in India and for us it also meant a considerable reduction in production costs."

Intellectual property protection in India has improved tremendously

The success of the seed coatings also led to demand for other Incotec technologies. "To serve the customer in India even better, to optimize our products to the crops and cultivation techniques in India, and to achieve further cost savings, we decided to move a larger part of the production to India," Bartels says. To protect the intellectual property rights of its special technologies, Incotec did not go the traditional route of applying for patents. "Not because this is poorly regulated in India - the protection of intellectual property in India has improved enormously in recent years - but because we have developed our own system for this," explains the MD. "The secret of the blacksmith still remains within the walls of the company."

Within Incotec, very few people know exactly how the products are manufactured or the techniques applied. "We work in all our branches worldwide 'on a need to know only basis'," says Bartels. "That means that each link in the process has only the knowledge they need to do their job. So the purchasing department knows what they have to buy, but not exactly what happens to those ingredients afterwards. In the factories, our people know what they have to do and also what the possible risks are of the substances they work with, but not exactly what the final product does. We also work with internal codes, so that outsiders cannot find out exactly what is in our products. It is similar to the way popular soft drink brands work. It tastes exactly the same in every country in the world, but the exact recipe and the details of the process are only known to a few."

The reforms will give the Indian farmer more money for innovative solutions

Incotec is the market leader in seed enhancement not only globally, but also in India. Yet many farmers in the country do not yet have the means to invest in the company's innovative solutions. "The agricultural sector in India has grown further mechanised in the time we have been active there, but is still far from being at the European level," says Bartels. "But we are now seeing two developments. On the one hand, India has to deal with climate change, which means that the start of the monsoon is shifting and the country is faced with greater weather extremes, such as longer periods of drought, but also more heavy rainfall. Agriculture must adapt to this. Seed companies and farmers would therefore like to invest in new technologies, but these are currently too expensive. On the other hand, the Indian government is implementing major reforms in the agricultural sector. Despite the fact that the Dutch top executive does not expect the sector to start a 'double digit growth' overnight, he does think that these reforms could have a positive impact on the farmers' income. "The reforms could lead to more choice and higher returns for farmers, giving them more money for innovative solutions. If these reforms also lead to an increase in scale within agriculture, agri will certainly be a sector to keep an eye on in the coming years."

Special webinar for successful sales in India

In February, we are organising India Business Month, during which you can attend free online sessions with all kinds of experts on doing business in India. On 9 February, the session is dedicated to selling goods and services in India. Oliver Mirza, Managing Director of Dr Oetker in India, will share his experiences on how the famous food brand had to adapt its products to the Indian market to become successful.