European companies operating or wanting to start production in India can use the MOOWR scheme to import (capital) goods to India in a smart and cheaper way. The scheme offers foreign companies the chance to invest in cutting-edge technology, allowing them to optimize their production processes in India and aims to modernize domestic industries. Here's how you, as a European company, can source smart by taking advantage of the MOOWR scheme.

By importing (capital) goods and under the MOOWR scheme European companies can benefit from low import duties and other incentives, making it an attractive way to expand and modernize your manufacturing operations in India.

Tax benefits of the MOOWR scheme.

If you use the MOOWR scheme, European companies get a deferral on paying import duties until the goods are cleared for domestic use or export to a subsequent location. The customs process is also relaxed, which means fewer documentation requirements, fewer physical inspections and faster clearance of products. This, of course, reduces administrative and operational costs.

But what makes the scheme especially attractive is the range of goods that can be imported advantageously under the scheme.

Economical sourcing under MOOWR

MOOWR may seem to focus on sourcing capital goods, but the scheme is much broader. Companies can economically source all elements needed for more efficient production, including raw materials, components and intermediate goods.

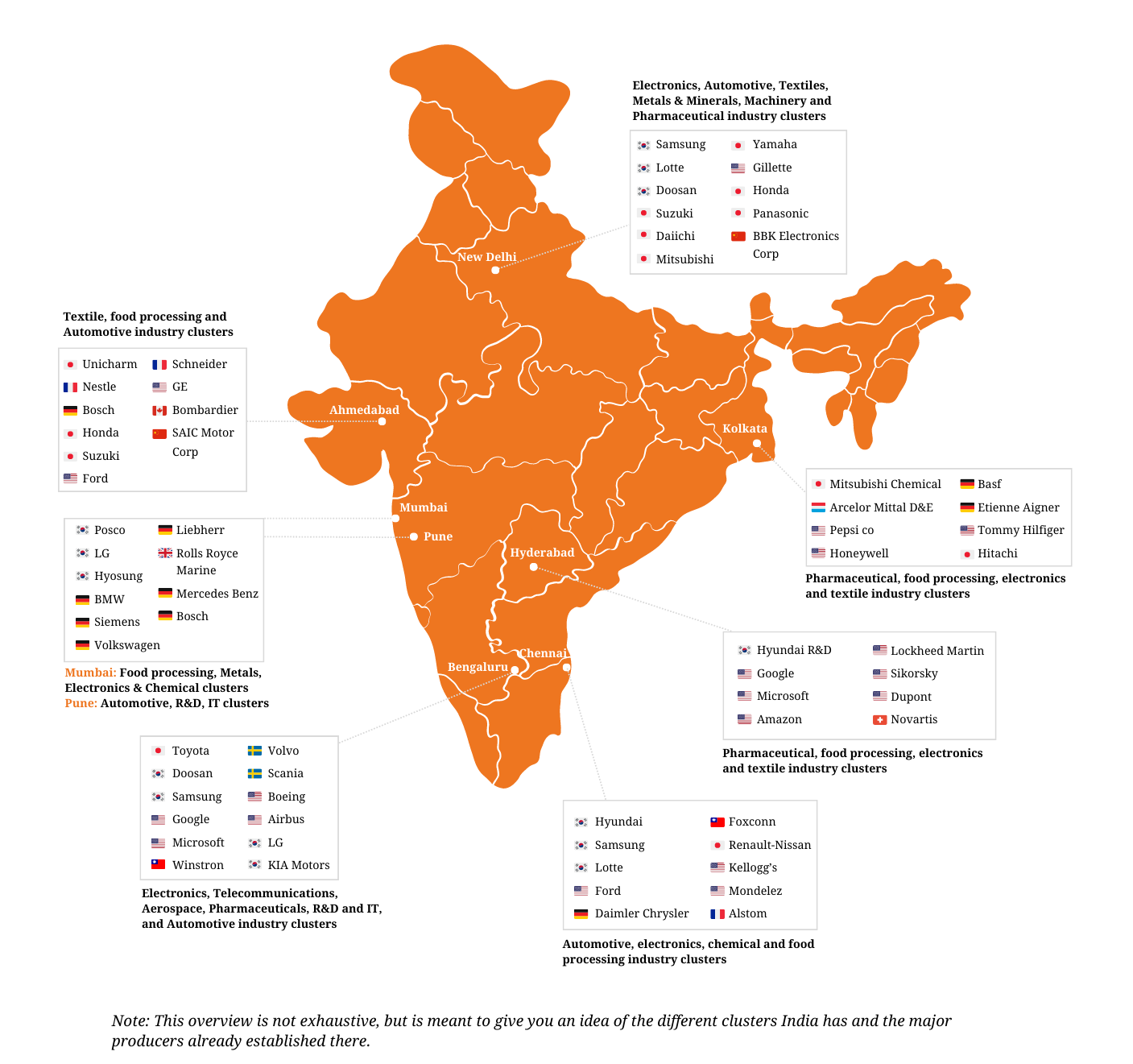

In addition, the MOOWR scheme also promotes cooperation between foreign companies and Indian suppliers. This cooperation not only facilitates technology transfer and knowledge sharing, but also strengthens the overall ecosystem by stimulating local industries and creating jobs.

Roadmap for sourcing through the MOOWR program

1. Find a suitable bonded warehouse

Find a bonded warehouse that meets your company's needs in terms of location, size and facilities. Consider both government-run and privately-run bonded warehouses in India.

2. Build a relationship with a bonded warehouse

Enter into a formal agreement with the warehouse operator. Obtain necessary licenses and approvals from relevant authorities.

3. Import capital goods

Purchase capital goods from both Indian and international suppliers. Import these goods into bonded warehouse and clear them under MOOWR scheme.

4. Manufacturing and other activities

Manufacture, process, pack and test goods in bonded warehouse. Store goods safely until ready for clearance.

5. Clear goods for domestic consumption or export

If the goods are ready for domestic consumption or export, apply for clearance. Pay deferred import duties at this stage.

Also take advantage of the MOOWR scheme

European companies looking to set up production in India should look into the benefits the MOOWR rulein offers them to get started and to import capital goods in a cost-effective manner.

Curious about the details of the program and how your company too could use this scheme in a smart way?

Shashank Verma

Vice President of Supply Chain Management

This article was written in collaboration with vice president of Supply Chain Management, Shashank Verma.

Verma has over 22 years of experience in establishing business strategies, managing the supply chain of hundreds of European companies, establishing sound logistics in India and other related functions with a focus on revenue growth and profit maximization of organizations.