If you want to start manufacturing in your own factory in India, you cannot simply copy-paste your European set-up. During the process, you need to take into account possible adjustments to your original plan so that your factory complies with Indian regulations and fits well with local practices. We will guide you through each step of the process and share pitfalls that many European companies fall into in India.

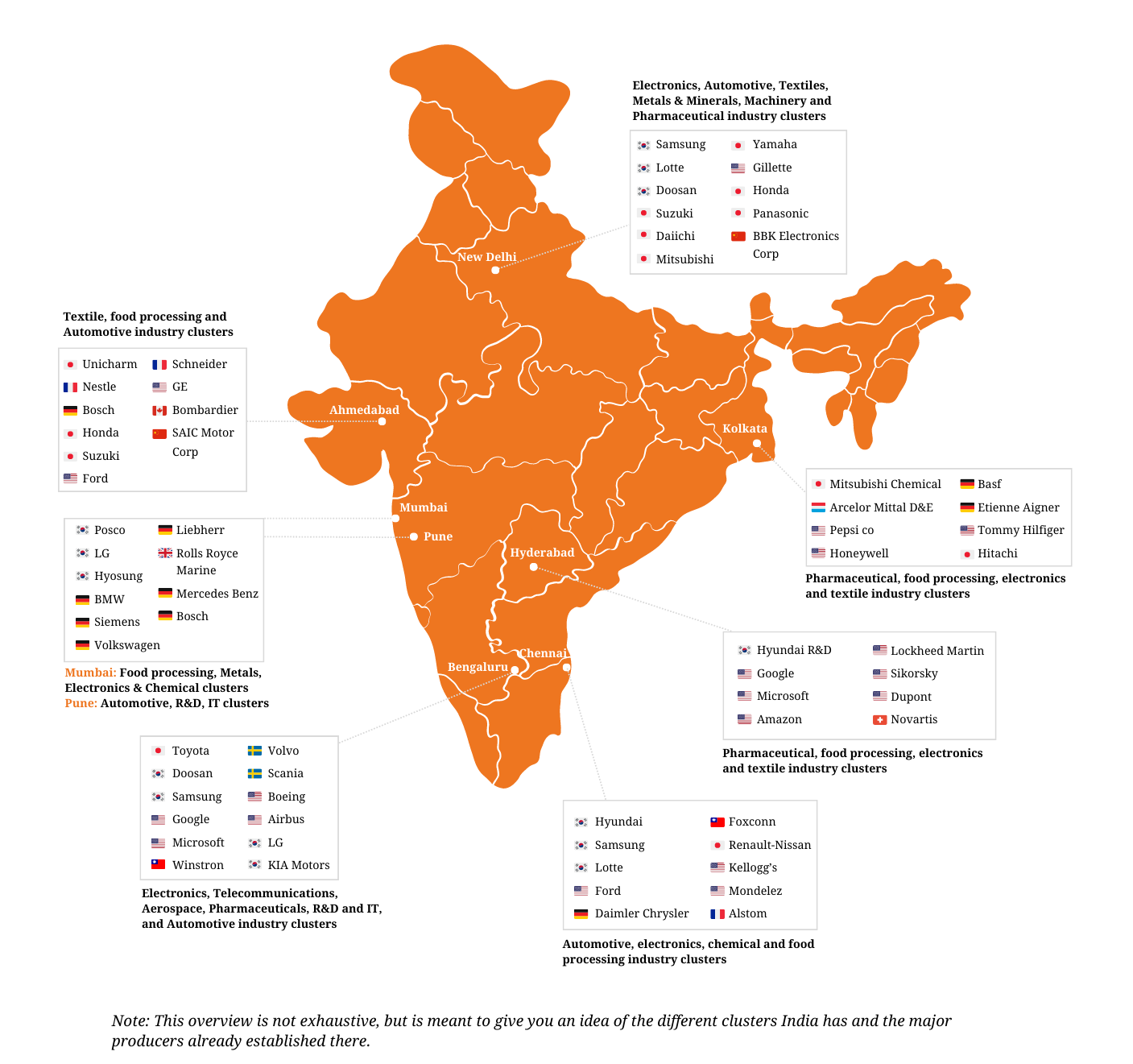

Finding the suitable location

As with finding a suitable producer, location choice when setting up a production facility is also very important. We often see European companies choosing a particular location because other companies within the industry or competitors have previously chosen that location.

No thorough location analysis is done in such a case to examine whether the necessary infrastructure is in place, whether the state or cluster has the right raw materials and semi-finished products, and whether enough and suitable personnel can be found. Choosing the wrong location can lead to irreversible problems in the long run, resulting in a departure from India.

This mistake can be easily avoided by engaging local experts who will conduct a location analysis across the country based on your needs and desires. It is important during this process to put aside any preferences and prejudices you may have and evaluate as objectively as possible the selected locations from the analysis.

After establishing a top three locations that meet your requirements, you can let your preferences factor into choosing the actual location and work with your local partner or consultant to find a suitable piece of land or existing facility that you would like to take over.

Brownfield investment

If there is a desire to establish one's own production site, but not to incur the high start-up costs associated with a greenfield investment (building one's own facility), then an existing facility can be sought to lease or purchase.

Such a brownfield investment is often done through an acquisition (M&A) of a local business. If this is chosen, the aforementioned location analysis can be expanded to include a partner search and due diligence once a potential partner is found.

There are interesting advantages to a brownfield investment:

costs are lower on average due to the use of existing facilities, infrastructure and personnel already employed,

it allows it to take over existing approvals and permits, saving a lot of work and time.

But there are also things that can work against it and should always be checked carefully before signing any potential agreement:

In India, production facilities often look "simpler" than in Europe, which does not mean that they produce lower quality as a result. If an acquisition is chosen, however, it must be carefully checked that the location meets European standards.

It is also important that the site has the proper permits to allow the facility to scale up or expand; you obviously want to avoid the possibility that you would not be able to adapt the facility to new production needs over time.

Therefore, if you choose to make a brownfield investment, it is important that you seek proper advice from a local expert with knowledge of your industry and Indian laws and regulations.

Purchasing land for a factory in India

If a greenfield investment is chosen, the establishment of its own production site, a suitable piece of land can be sought based on the result of the site analysis.

This was always a considerable challenge in India, but the Indian government is working hard to make industrial zoned land available making the search less time consuming these days. Still, it is very wise not to have a hard deadline for finding a suitable plot as it generally takes more time than expected.

In addition, the price of lots in clusters and other popular destinations can be high, making European companies decide to specifically look for cheap land. Watch out for this; there can be very nasty snags in this.

Often in these types of deals, it is said that the land has an industrial destination, but this is not the case. If a lot is purchased that later turns out to be agricultural or private zoning, it is almost impossible to get it changed and another option will have to be sought.

We therefore recommend that you look specifically for industrial lots offered by the government. Finding suitable options listens closely in India and help from a local expert in this field is therefore not a luxury.

Prepare well for setting up your production in India

Many of our clients, before making the decision to set up production in India, want to have a good understanding of what is involved in setting up a production site in India. IndiaConnected has therefore compiled all the tips and advice in a special guide on setting up your own production site in India or finding the right Indian manufacturing partner.